Intro

Discover 5 innovative ways foam forms enhance construction, packaging, and crafting, offering versatility, insulation, and protection, while exploring related techniques like foam cutting and molding.

The versatility of foam is a marvel of modern technology, with its applications ranging from the mundane to the extraordinary. From the comfort of our daily lives to the precision of industrial processes, foam plays a crucial role. Understanding how foam forms and the various ways it can be manipulated is essential for appreciating its widespread use. The process of foam formation is complex, involving the mixture of liquids, gases, and solids in a way that creates a lightweight yet robust material. This article delves into the different ways foam can be formed, exploring both the scientific principles behind these processes and the practical applications that make foam an indispensable material in numerous industries.

The importance of foam cannot be overstated. It is used in everything from the cushions we sit on to the insulation that keeps our homes warm in the winter and cool in the summer. Foam is also a critical component in many industrial applications, including the manufacture of automotive parts, the production of medical devices, and the creation of protective packaging. The ability to form foam into various shapes, sizes, and densities has made it an incredibly versatile material. Moreover, advancements in technology have led to the development of new types of foam with unique properties, further expanding its potential uses.

As we explore the ways foam forms, it becomes clear that the process is not just about mixing ingredients together but involves a deep understanding of chemistry, physics, and engineering. The formation of foam is a multifaceted process that can be approached from different angles, each yielding distinct types of foam with its own set of characteristics. Whether it's the creation of flexible foam for furniture, rigid foam for insulation, or specialized foam for biomedical applications, the method of formation is crucial. This article aims to provide a comprehensive overview of the various foam formation techniques, highlighting their principles, applications, and the benefits they offer.

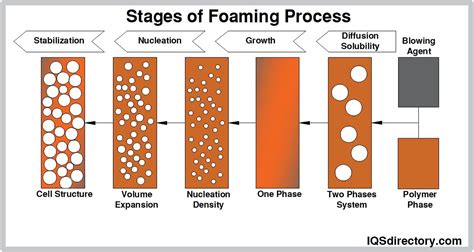

Introduction to Foam Formation

The formation of foam involves the introduction of gas into a liquid, creating a network of bubbles that gives the material its characteristic lightness and flexibility. This process can be achieved through various methods, including mechanical agitation, chemical reactions, and the use of specialized equipment. Understanding the basics of foam formation is essential for developing new applications and improving existing ones. The properties of the resulting foam, such as its density, strength, and durability, are directly influenced by the formation process.

Chemical vs. Physical Foam Formation

The distinction between chemical and physical foam formation is fundamental. Chemical foam formation involves a reaction that produces gas, which then gets trapped in the liquid, creating foam. This method is commonly used in the production of polyurethane foams. On the other hand, physical foam formation relies on the mechanical introduction of air or gas into the liquid, a process often used in the manufacture of soap and detergent foams. Each method has its advantages and is suited to different applications, depending on the desired properties of the foam.Methods of Foam Formation

There are several methods through which foam can be formed, each with its unique characteristics and applications. These include:

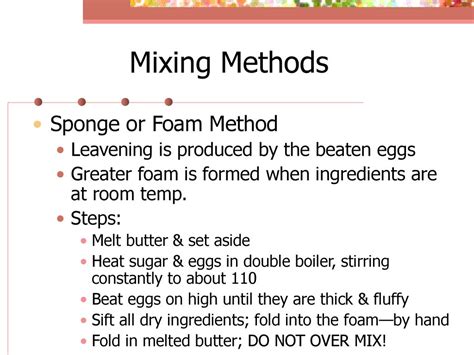

- Mechanical Foam Formation: This involves the use of mixers or agitators to introduce air into a liquid. The process is commonly used in the food industry for products like whipped cream and meringues.

- Chemical Foam Formation: As mentioned, this process involves a chemical reaction that produces gas, which is then trapped to form foam. It's widely used in the production of plastics and rubber.

- Thermal Foam Formation: Some materials can form foam when heated, due to the expansion of gases within them. This method is less common but has specific industrial applications.

- Electrostatic Foam Formation: This is a more specialized method where an electrostatic charge is used to create foam from certain materials. It's an area of ongoing research with potential applications in nanotechnology and materials science.

- Biological Foam Formation: Certain biological processes can lead to the formation of foam, such as the foaming that occurs in some fermentation processes. This area has applications in bioengineering and the production of bio-based materials.

Applications of Foam

The applications of foam are incredibly diverse, reflecting the wide range of properties that can be achieved through different formation methods. From the comfort and support provided by foam in mattresses and cushions to the critical role it plays in safety equipment like helmets and life jackets, foam is an integral part of modern life. Additionally, foam is used in filtration systems, as a medium for plant growth in hydroponics, and as a component in the manufacture of composite materials.Advancements in Foam Technology

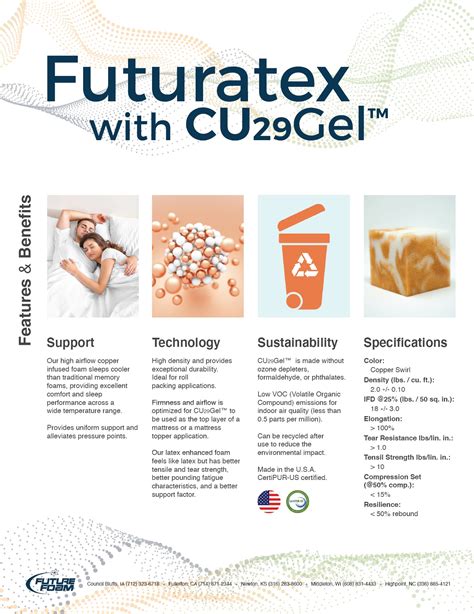

Recent advancements in foam technology have focused on developing more sustainable and environmentally friendly foams. This includes the use of bio-based materials, the reduction of volatile organic compounds (VOCs) in foam production, and the development of foams with improved recyclability. Furthermore, research into nanocellular foams and other advanced materials is opening up new possibilities for foam applications, including in fields like aerospace and biomedical engineering.

Sustainability and Foam

As with many materials, there is a growing concern about the environmental impact of foam production and disposal. Efforts to make foam more sustainable include the development of foams from renewable resources, improving the energy efficiency of manufacturing processes, and designing foams that are more easily recyclable. Consumers and manufacturers alike are becoming more aware of the need for sustainable practices, driving innovation in foam technology towards more environmentally friendly solutions.Future of Foam Formation

The future of foam formation is promising, with ongoing research and development aimed at creating new types of foam with unique properties. The integration of foam technology with other fields, such as nanotechnology and biotechnology, is expected to yield innovative materials and applications. Moreover, the push towards sustainability is likely to drive significant advancements in how foam is produced, used, and disposed of, ensuring that this versatile material continues to play a vital role in various aspects of our lives.

Challenges and Opportunities

Despite the many advantages and applications of foam, there are challenges to be addressed, particularly in terms of sustainability and environmental impact. The development of more eco-friendly foams, improvement in recycling technologies, and reduction of waste are critical areas of focus. Additionally, as new applications for foam emerge, there will be opportunities for innovation and growth, both in terms of the materials themselves and the processes used to create them.Conclusion and Next Steps

In conclusion, the formation of foam is a complex and multifaceted process, with various methods and applications that underscore its importance in modern technology and daily life. As we look to the future, it's clear that foam will continue to play a significant role, driven by advancements in technology and the need for sustainable solutions. Whether through the development of new materials, the improvement of existing processes, or the exploration of novel applications, the field of foam formation is ripe with opportunities for innovation and growth.

What are the main methods of foam formation?

+The main methods include mechanical, chemical, thermal, electrostatic, and biological foam formation, each suited to different applications and materials.

What are some common applications of foam?

+Foam has a wide range of applications, including in furniture, insulation, safety equipment, filtration systems, and biomedical devices, among others.

How is foam technology becoming more sustainable?

+Efforts to make foam technology more sustainable include the use of bio-based materials, reduction of VOCs, improvement in recycling technologies, and the development of more energy-efficient manufacturing processes.

We invite readers to share their thoughts on the future of foam formation and its potential applications. Whether you're an industry professional, a researcher, or simply someone interested in the science behind everyday materials, your insights are valuable. Please comment below or share this article with others who might be interested in the fascinating world of foam. Together, we can explore the possibilities that foam has to offer and work towards a more sustainable and innovative future.